The First In-Line 3D AI Dimensional and Quality Inspection Solution

Fast deployment and ROI

>99.7% Reliability

Sub-mm Accuracy

Patented 3D-AI platform that integrates advanced camera calibration with accurate CAD alignment and leverages accelerated pre-trained large AI models

Dimensional AI Inspection — Verifies presence, tolerance, and quality

Rapid Deployment — Pre-trained large AI models support most manufacturing features

In-line within the Cycle Time — 100% of parts and features, every cycle

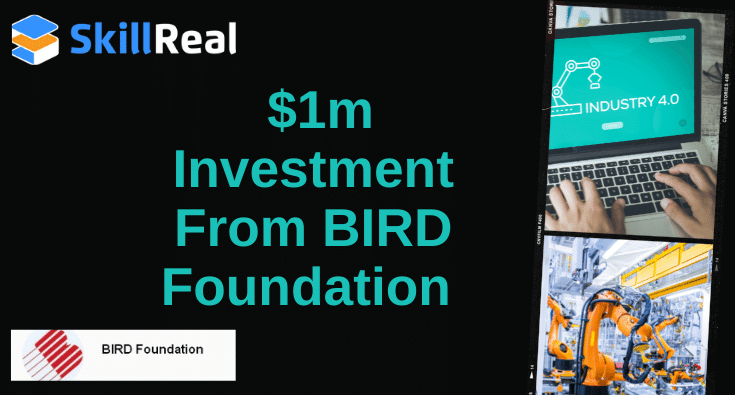

CAD-Based Measurement — Aligns physical parts with digital twins

Zero Footprint — No robots, jigs, or dedicated cells required

Immediate ROI — Cuts manual labor and quality-related costs

One Solution. Many Use Cases.

Reduce design iterations whilst saving time and prototypes costs with Virtual prototype

Virtual prototype

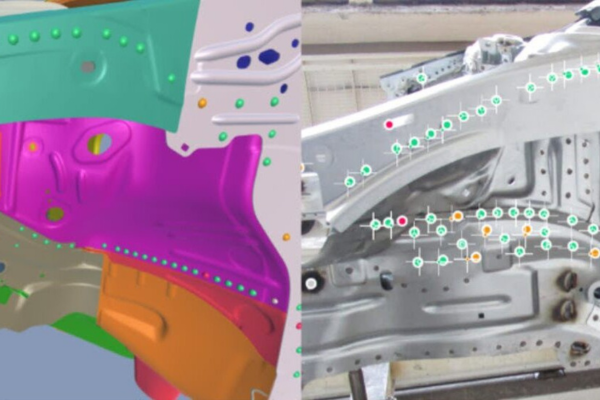

Inspect spot welding, studs and manufacturing quality and tolerances.

Weld point inspection

Ensure real-time alignment of digital and physical twins with faster commissioning times

“As Built vs as Designed”

SkillReal’s Patented Technology

SkillReal’s open platform combines advanced computer vision, CAD-based tracking, and pre-trained AI to deliver sub-mm inspection with standard cameras. It eliminates jigs, enables real-time quality and dimensional checks, and is ready to deploy on day one. The system integrates easily with existing tools for fast, scalable implementation.

Automotive Aerospace Battery Heavy Machinery

Solution Partner

Jointly Bringing Best-in-Class Digital Twin Manufacturing Solutions to Siemens Customers Worldwide