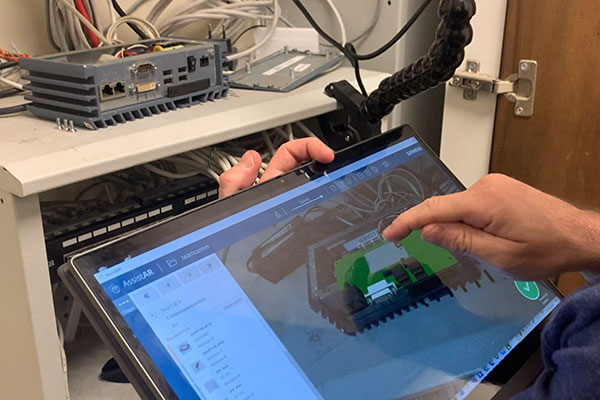

SkillReal AssistAR provides live-work instructions and validation using patented AR inspection technologies. 3D models and assembly steps are automatically sourced from the PLM/ERP system.

SkillReal AssistAR can be used for complex assemblies, highly configurable products and manufacturing with high error costs. Working with AssistAR can cut costs, enhance productivity and reduce assembly errors. It also reduces the errors that result from having to prepare and constantly update work instructions and enables shorter onboarding time for new employees.

Supported Manufacturing Line Use Cases

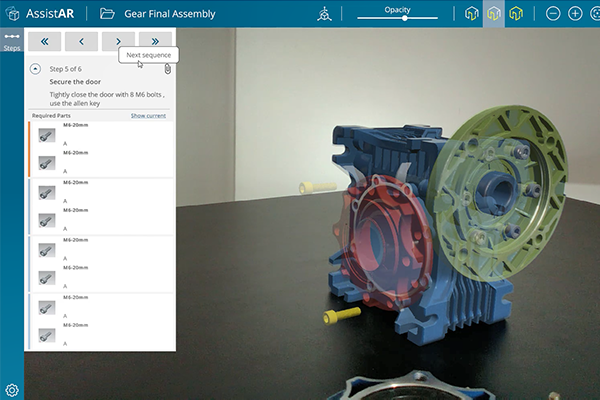

Live Assembly Instructions

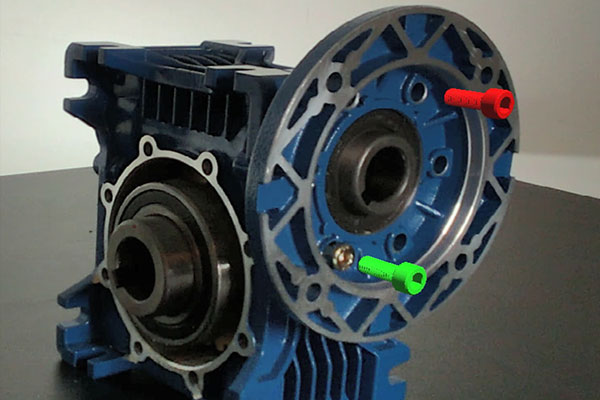

Assembly Validation

Maintenance Instructions

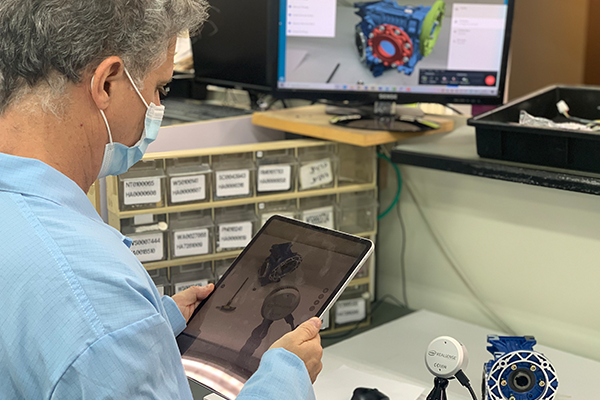

Shop Floor Employee Training and Technicians’ Training

Remote AR Support and Guidance

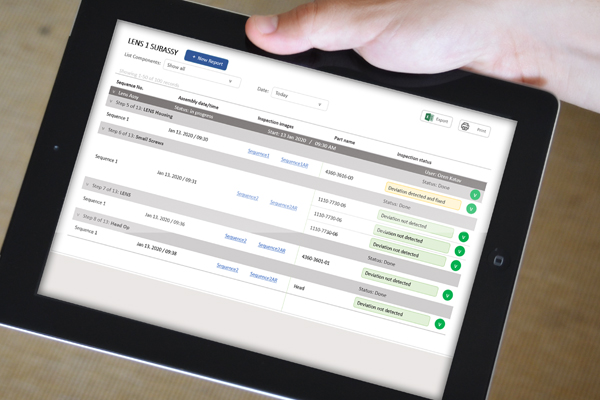

Assembly Quality reports

Improve Performance in Every Angle

Time efficiency

- No need to spend time on work instructions preparations and updates

- Faster assembly

- Minimize frontline workers ramp-up time

- Eliminate the need for specific inspection stations

Quality

- Validation on each assembly step for assembly error detection

- Automated record of task completion

- Clear and accurate marking of actual parts for remote expert support

Cost savings

- Bridge workers’ skill gap

- Faster ramp-up time

- Minimize losses - reduce errors, rejects and rework

- Lower travel costs with remote expert support

Seamless Integration

within PLM Systems

Plug-and-play integration within PLM/MES systems, allows AssistAR to automatically access and retrieve the most up-to-date work instructions and 3D models. This eliminates the errors that occur in the preparation and updating of work instructions and the resulting costs to rectify them.

Watch SkillReal AssistAR in action