SkillReal

Inline SW Inspection Platform

Greater efficiently at all stages – from Prototype to pre-serial to serial production

R&D Prototype stage

- Reduce risk of crash or durability failures

- Save rework or costs of retest

- Identify and rectify missing or mis located welds/studs/features early

Launch Phase / Pre-serial production

- Fast inspection with closed loop robot reprogramming

- Early detection of missing and mislocated features such as welds, studs/holes

- Reduce risk of scrap, rework, validation and other failures

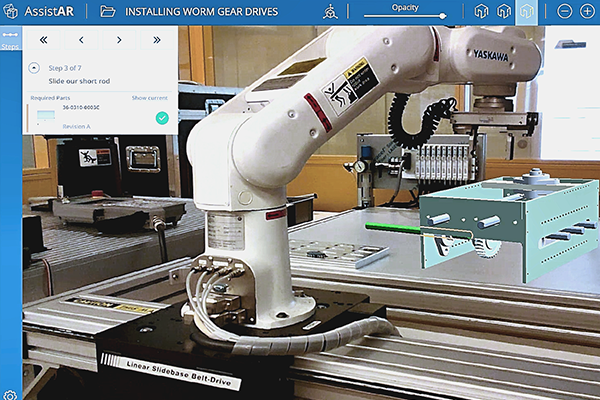

- Easy to deploy and use by the shopfloor technicians

Serial Production

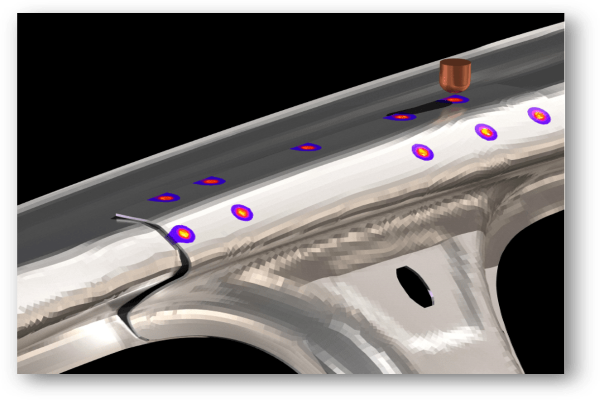

- Inspect every part at every station with sub-mm accuracy

- Robots’ predictive maintenance

- Measure and alert on deviations and quality issues

Supported Manufacturing Line Use Cases

Verify “As-built vs. As-designed”

Process Points Marking & Inspection

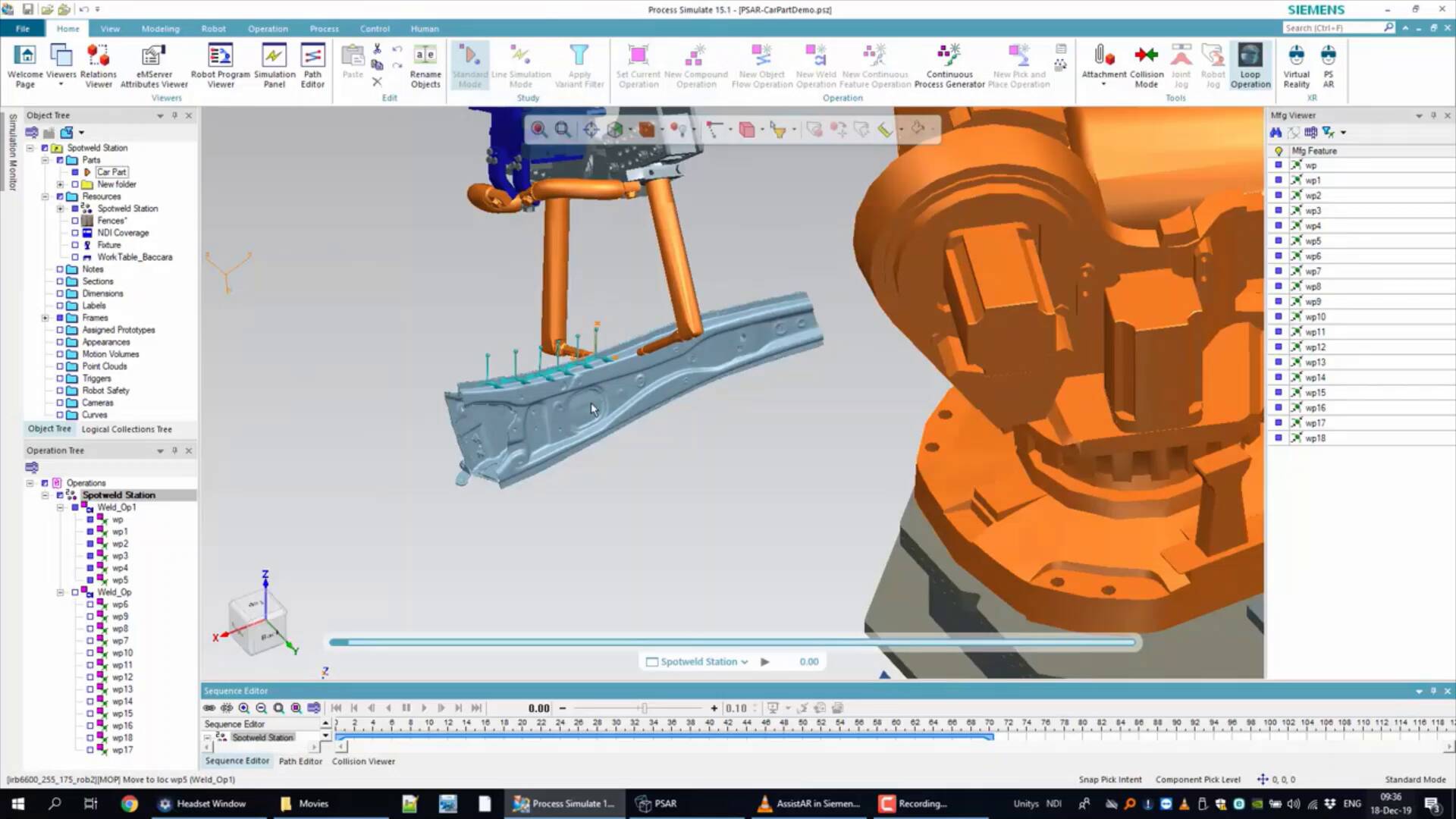

Virtual Prototypes & Robot PROGRAM CALIBRATION

SUB-MM 3D measurements AND INSPECTION OF MANUFACTURED FEATURES LIKE WELD POINTS, STUDS

PROCESS POINTS INSPECTION, ALIGNMENT AND MARKING

Save Costs, Shorten timelines and Improve Quality

Time efficiency

- Shorter commissioning process

- More effective processes with virtual prototyping

- Inspection capabilities to identify errors and to reduce down time

Quality

- Ensure ‘built as designed’

- Early identification of errors

- Accurate inspection of process points of manufactured parts

Cost savings

- Early detection and error solving

- Save on prototype and gage costs

- Lower traveling costs of experts who can now inspect remotely

- Shorter down time and reduced time to market

Seamless Integration

with PLM/MES Systems

Plug-and-play integration with PLM/MES systems, automatically accessing and retrieving most updated work instructions and 3D models. This eliminates errors and costs derived from the preparation and updating of the work digital twins.

Watch SkillReal Digital Alignment in action